Self-lubricating bearings are widely used at home and abroad for their unique properties and economy.

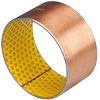

Picture of self-lubricating bearing

The copper sleeve matrix is made of high-strength and high-hardness copper alloy, which is more than twice the hardness and strength of the ordinary copper sleeve. The surface of the copper sleeve is drilled and inlaid with graphite-based oil-containing solid lubricant, the lubrication area accounts for about 25%, and a layer of solid-liquid mixed lubricating film is generated by the bearing itself during operation, which has the effect of reducing friction and greatly improving the performance of the copper sleeve itself. It can work normally in harsh working conditions such as heavy load, high temperature, impact load, reciprocating motion, water, and difficult to refuel. However, the ordinary copper sleeve wears out faster due to the failure of the oil film and cannot even be used. The product has a history of nearly ten years and has been widely used in various industries across the country. With the understanding of this product, the scope of use will become larger and larger, and it will surely produce good benefits to the society.